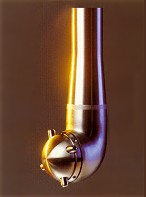

SaniJet 20

The SaniJet 20 is a sanitary cleaning device of the rotary jet head type, for permanent installation that provides a 360° indexed cleaning pattern. The SaniJet 20 is completely self-cleaning and self-draining and has an integrated self-cleaning downpipe (patent pending).

The SaniJet 20 is a sanitary cleaning device of the rotary jet head type, for permanent installation that provides a 360° indexed cleaning pattern. The SaniJet 20 is completely self-cleaning and self-draining and has an integrated self-cleaning downpipe (patent pending).

The drive mechanism is located outside the tank or process equipment leaving a minimum of parts to be submerged into the product. All product contact surfaces are either AISI 316L stainless steel or FDA approved polymer

materials.

Applications

The SaniJet 20 is designed for use in pharmaceu-tical, biotechnological, food and dairy processing applications. Tanks and vessels between 0,5-30 m3 (130-8,000 US gallons). The design makes the SaniJet 20 especially well suited when processing high viscous, foaming or thixotropic products and in chemical processing applications, where product cross contamination is unacceptable and must be avoided.

Cleaning Pattern

The SaniJet 20 utilises the patented “Golden Section” cleaning pattern (see back page). The distance between the tracks of the jets ensures an efficient removal of remaining product from the tank surface right from the beginning of the cleaning sequence, allowing for short cleaning time. Exampel – 2 nozzle machine

Options

Available as media driven or motor driven (electrical/air). The motor driven versions are equipped with a magnetic clutch providing a leakage-proof transmission. The air motor provides an effective drive for low flow machines in rough environments and for use in explosive hazard zones, provided it is installed according to safety instructions. The air motor has variable speed in order to adjust cleaning intensity.

An electronic rotation sensor to validate 360° coverage can also be included. On request, the machine can be supplied electro-polished.

Quality System

The SaniJet 20 is designed in accordance with the EHEDG design requirements for sanitary design of processing equipment. It is produced according to Toftejorg’s ISO 9001 International Standard certified design and manufacturing procedures.

Cleaning Pattern, The Golden Section

SaniJet 20 operates according to the patented Golden Section cleaning pattern (EP-Patent No.: 0495883, US-Patent No.: 5,279,675), which is unique in building up the pattern in an ultimate uniform way. The pattern starts very coarse and refines itself in a step-less way by laying out the tracks approximately in the middle between the two most distant tracks already made. This means, that the jets always clean the areas containing most remaining product, and thereby remove as much deposit as possible in the shortest possible time.

In case a complete cleaning pattern is not required, it will be possible to reach the same cleaning level within half the time and by using half the amount of cleaning fluid compared to a traditional step-wise cleaning pattern. Furthermore, due to the uniform cleaning pattern, the cleaning can be stopped at any time, whereas with traditional non-uniform cleaning pattern this would not be advantageous. However, after the complete cleaning pattern has been established, the difference between the Golden Section and the traditional stepwise cleaning pattern is negligible. Golden Section Traditional cleaning pattern cleaning pattern.

Specification

Materials

AISI 316L, PEEK, E-CTFE

Sealing: EPDM Polymers FDA-approved 21 CFR §177

Surface Finish

Product contact surfaces: Ra=0.8 µm

Weight

Media driven machine 9,5 kg (21 lbs)

Electrical driven machine 11,8 kg (26 lbs)

Air driven machine 11,7 kg (25.8 lbs)

Lubricant

Machine: Self-lubricated with the cleaning media

Air motor: Can operate non-lubricated

Working pressure

3-13 bar (45 -185 psi)

Recommended pressure

3-8 bar (45-115 psi)

Max. working temperature

90 °C (194 °F)

Max. ambient temperature

140 °C (284 °F)

Effective throw length

1.5-4 m (5-13 ft)

Inlet connection

Clamp: 1″ ISO 2852

Min. tank opening

3″ clamp (ø73 mm/2.87″) max. 50 mm/2″ high

Tank connection

Clamp: 3″ ISO 2852